STERILIZATION PROCESS SIMULATION

XRAY - EBEAM - Co60

DOSE CALCULATIONS – IRRADIATION PROCESS SIMULATION & OPTIMISATION

DOSE CALCULATIONS – IRRADIATION PROCESS SIMULATION & OPTIMISATION

SETUP YOUR STERILIZATION PROCESS AND SIMULATE EVERY DOSE MAPPING

RayXpert is a software solution that associate a 3D modeling tool to a powerful computer calculation code. It allows to simulate Xray, Ebeam and Gamma Radiation Processing application in order to increase the performance and quality of your Industrial process.

Regarding to current dosimetry methods, purely experimental, RayXpert will give you access to powerful forecasting methods, and to all the reliability and responsiveness that a simulation tool provides

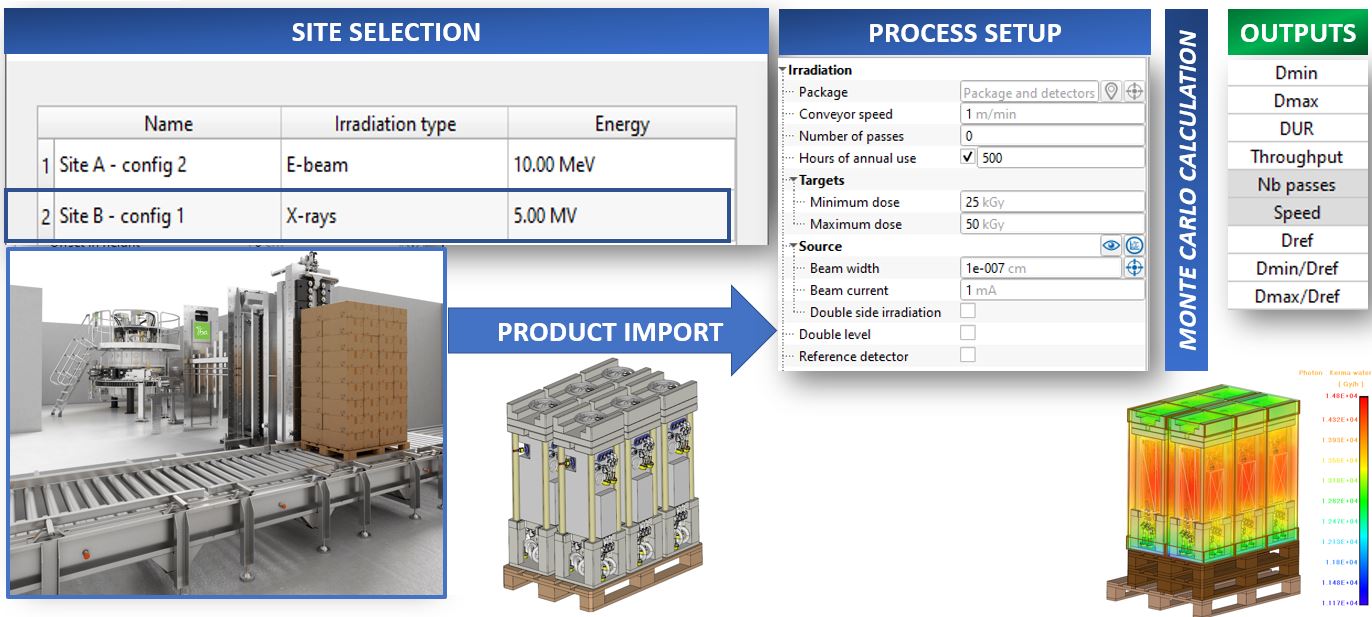

3 STEPS PROCESS

for Product Manufacturers & Sterilization service providers

BENEFITS FOR BIO-MEDICAL PRODUCT MANUFACTURER

Xray sterlization process simulation

TRAD - IBA - SARTORIUS - AERIAL

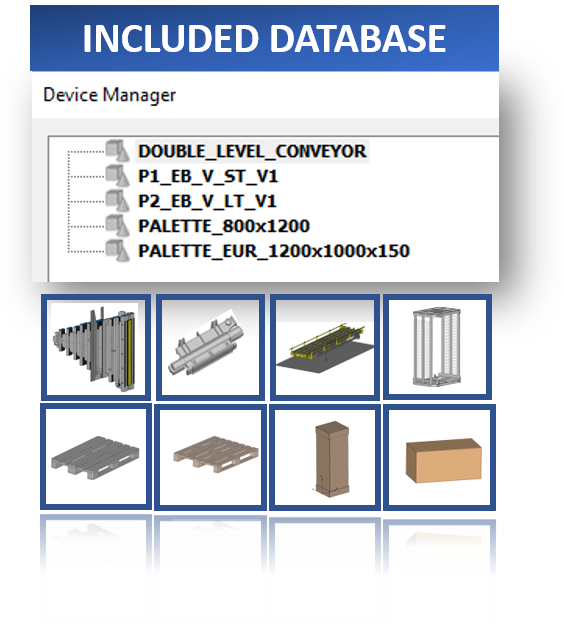

USE AN ALL INCLUDED DATABASE OF SOURCES AND CONVEYING SYSTEM

FACILITATE DOSE MAPPING

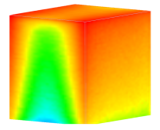

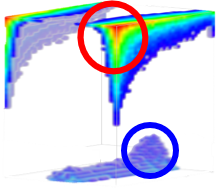

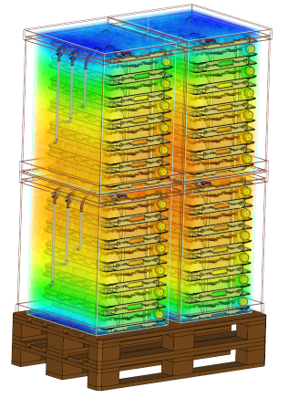

- Monte Carlo Simulation can calculate dose at any point in the products (3D dose

mapping) - It defines the zones of lowest dose and highest dose

- It is a perfect tool to identify the zones where the dosimeters should be placed

during dose mapping, hence easing the dose mapping and reducing its cost while

guarantying its quality

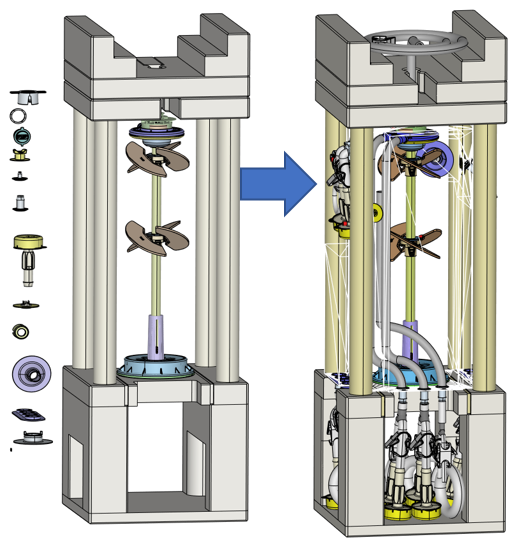

ACCELERATE PRODUCT DESIGN

- Take into account radiation impacts at an early phase of the design process.

- Import the product 3D model and anticipate the dose everywhere without requiring a physical prototype.

- Spot the Maximum dose areas and verify doses in sensitive components.

- Reduce the number of prototyping iterations and accelerate the time-to-market

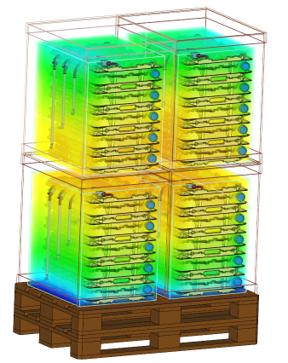

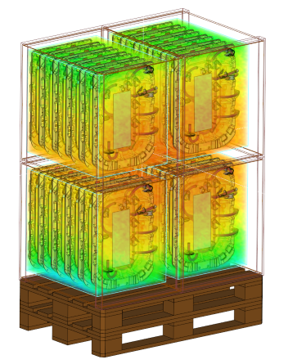

INCREASE PRODUCTIVITY

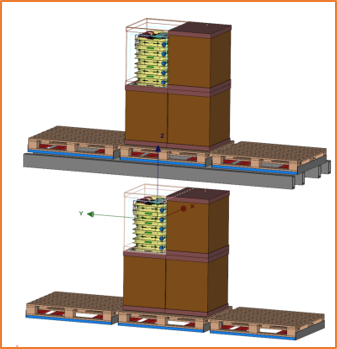

Optimize the product configuration and packaging

- Increase number of products in a box or on a pallet

- Increase the Minimum dose

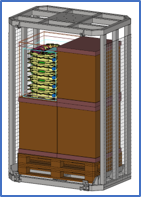

HORIZONTAL

VERTICAL

+20% MORE PRODUCT

SELECT IRRADIATION CENTERS

- Verify if dose distribution (Dmin, Dmax, DUR) can be achieved in any irradiation sites

- Adapt the product repartition between sites

- Support transferring products from gamma to X-ray/Ebeam

TOTE CONVEYOR

2 LEVEL CONVEYING SYSTEM